CALL US 888-825-4716

Maintenance

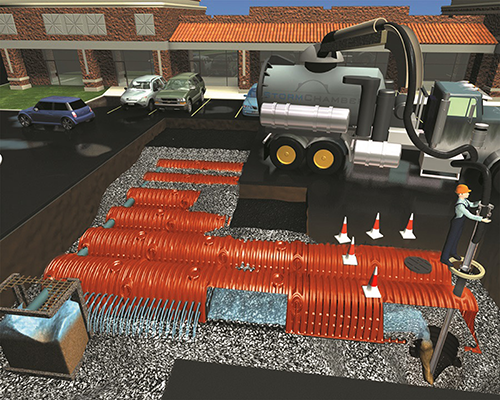

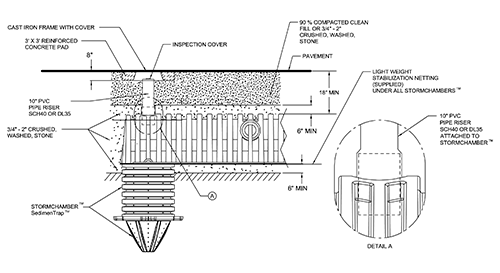

The StormChambers are designed with a defined top portal area at the “down-flow” end of the chamber which can be cut out to accept a riser pipe up to 10 inches in diameter. The riser can be used as an observation well and to allow a vacuum truck tube to remove sediment from the underlying patented “SedimenTrap”. The “down-flow” ends of the StormChambers have end walls which are closed on the bottom and function similar to a coffer dam, with most of the sediment depositing into the adjacent sediment trap prior to flowing into the next chamber. This facilitates its removal through the riser pipe located directly above. It is recommended that the sediment traps and clean-out risers, at a minimum, be placed at the first and last chamber of each row of StormChambers which receive the flow from the storm water inlet(s).

Sediment should be removed when deposits approach within six inches of the invert heights of connecting pipes between StormChamber rows, or in sumped inlet structures. The needs of each site are different and so the necessary maintenance schedule will vary with each site. To determine the best schedule the sediment traps should be inspected quarterly and after each major storm event. It is recommended that a logbook be kept of each observation to determine the depth of the water in the StormChamber systems and how quickly the system is dewatered. Once the performance characteristics are determined a monitory schedule can be created based on the unique needs of the individual site. Research demonstrates that labor costs for cleaning one SedimenTrap with a vacuum truck is approximately $50.00.

The use of fully grated inlet structures will keep the vast majority of debris out of the StormChamber System. Inlet structures with a 2-4 foot sump are recommended. This will allow for additional capture of sediment that can easily be removed with a vacuum truck or other device before it gets into the StormChamber system. The addition of a Snout, by BMP Inc., or similar structure over the outflow into the StormChamber system will retain flow tables within the inlet structure.

It is highly recommended that the StormChamber system not be opened to receive storm water flows until construction of the site has been completed. Even then, all storm water inlets must be protected from sediment loading until the site is completely stabilized. Complete stabilization implies that the construction site has been cleared of construction-related debris and has incurred at least two storm events sufficient to wash most soil and other particulate matter off impervious surfaces.